Dòng CX

Developer Interview

The aim of the CX Series: A bright sound that sings

We had three objectives in the design of the new CX Series; solid support for the bracing, a soundboard that vibrates as freely as as possible, and a tone that matches the directionality of the sound produced from the instrument’s body. This directionality is fundamentally the same as that of Yamaha's flagship CFX concert grand; in fact you could say that they were developed based on the same concept.

For the C3X and upwards - larger models that demand a certain level of volume - we improved the rigidity of the bracing to provide stable support, and created a design that allowed the soundboard that sits on top of the bracing to vibrate freely. For the sound, we utilized a new type of string, and carefully tested the quality of the hammer felt.

Our aim was to achieve a sound that would "sing" brightly. A unique aspect to the CX Series is the focus that we applied to those areas that are vital to a piano, such as the construction of the soundboard, the tone that emerges from it, and the exterior of the instrument. Of all the lineup changes that Yamaha pianos have undergone over the last couple of decades, this series represents the most broad-reaching improvement, and as a result the musciality of these pianos has been greatly enhanced.

We wanted to craft a soundboard that would want to sing and produce sound

Just as with the CF series, our research emphasized the control of internal stresses within the soundboard, and we were able to make some significant advances. The resulting sound offers a quick response, bright tone, and clean harmonies. We believe that improving the response of the soundboard, that is, improving the efficiency of its acoustic radiation, makes the most of these qualities, and offers a broader range of expression.

Basically, we want to provide instruments that want to sing, instruments that want to deliver sound. Rather than instruments that you really have to work to get a sound out of, we wanted to craft pianos with a soundboard and body that would actually want to sing, to make sound. In that sense, this soundboard, with its new structure, responds well to any input and we believe that it offers a much broader range of expression in its response.

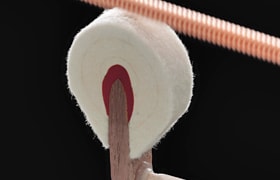

Strings that give pure harmonies; hammer felt with a rich tone.

Next, we had to decide upon what tone we should give this "singing" body, and this soundboard with its superb response. Two of the major factors in this sound were the strings and hammers. For this series, we selected music wire (strings) with beautiful overtones and clean harmonies, good sustain, and a tone that carries. We obtained sheets of felt, which we refer to as "raw cloth," and crafted the piano hammers in Yamaha. The felt used in the CX Series is checked carefully and is extremely resilient, giving it a full, deep tone. The combination of this music wire and hammer felt have further enhanced the uniqueness of CX Series pianos.

Designers are constantly driven by the desire to craft even better instruments.

A piano is an extremely complex system made up of a large number of parts. Moreover, the sound of a piano is significantly affected by variations in the timber and natural materials from which it is made, and by the conditions in which it is played - even rainy weather will change the way a piano sounds. The sound of a piano will also change depending on who tunes it. When designing a delicate instrument like the piano, which is affected by so many variables, the key is to minimize the effect of factors fuch as the enviornment. It is therefore essential to understand how to address these factors, as well as to possess the craftsmanship and production skills to create instruments that do not vary.

It is also important to evaluate pianos correctly during the development process. This is not something that we do ourselves; instead we have top-flight pianists play them and offer their opinions. This sometimes reveals aspects that we, as developers were not aware of, so we emphasize the accumulation of this information. Making even a single mistake in this process can sometimes result in a piano with many good points receiving a bad evaluation. In order to keep the scope for mistakes at a minimum, I think that it is important to have the technical ability to obtain the same result from a production process - no matter how many times it is carried out - in order to obtain a positive and accurate evaluation of those good points.

However, I don't think that that any designer is likely to say, that an instrument is perfect and that they are completely satisfied." Instruments exist within the context of musical expression, and music itself has no limits. If you think about all the different varieties of music, it’s almost impossible for a single instrument to be "the best." Even now, I often find myself thinking, "hmmm... if I had only things this way this instrument would have been something great," or, "if I could find a way for the instrument to help the performance with this kind of nuance, it would be more musically expressive." As we develop these pianos, we designers always have an image of a much, much better instrument; there is probably no end to our drive to achieve more.

Yutaka Matsuki

Piano Design Section Manager.

Joined Yamaha in 1992. After beginning work at Yamaha, Matsuki was principally tasked with developing upright pianos, and was involved in the creation of the SU7 and other instruments. After gaining additional experience developing grand pianos, he was asked to work on the development of the CF Series, which was released in 2010.

Currently, Matsuki is involved in the development of the core areas that give acoustic pianos their fundamental performance characteristics.